3004 aluminum sheet is widely used in pop cans, aluminum fin stock, chemical equipment, fuel tanks,etc. We supply 3004 aluminum alloy with different tempers and surface treatments. Inquire now!

3004 aluminum sheet is an aluminum-manganese alloy (containing 1.0%-1.5% manganese and 0.8%-1.3% magnesium). It possesses excellent corrosion resistance (especially against seawater corrosion), good formability and weldability, and its strength is higher than that of 1xxx series aluminum alloys. It can be strengthened through processes such as H18.

Compared to 3003, 3004 alloy is superior in tensile/yield strength, corrosion resistance, and weldability, while maintaining good formability and low-temperature toughness, making it suitable for more demanding industrial applications.

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others (each) | Other (total) | Al |

3004 | 0.30 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | 0.25 | 0.25 | 0.05 | 0.15 | Remainder |

Alloys | 3004 aluminum plate |

Tempers | F,O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H111,H112,H114,etc. |

Thickness | 1-500 mm |

Width | 100-2650 mm |

Length | 500-16000 mm |

Tempers | Tensile strength(σb) | Yield strength(σ0.2) | Elongation(δ5,Minimum value) |

O(Annealed state) | 170-210 | ≥70 | 25 |

H34(Semi-hard state) | 240-280 | 200-250 | 8 |

H38(Fully hard state) | 280-320 | 240-290 | 5 |

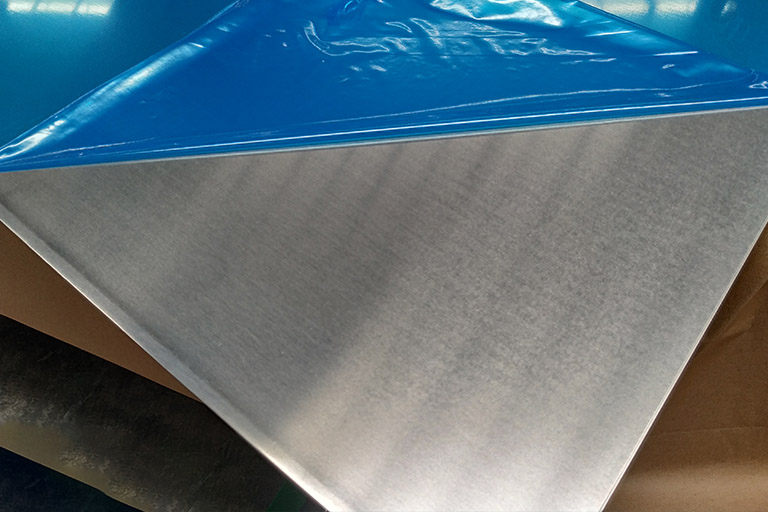

Plain sheet

Plain sheet with a PVC coating on one side

Aluminum tread sheet

Aluminum tread sheet with a PVC coating on one side

Coated aluminum sheet

AA 3004

UNS A93004

ASTM B209 3004

EN 573-3 AlMn1Mg1

Recommended Minimum Bend Radii for 90-Degree Cold Forming of Sheet of 3004

(Reference test method – ASTM E290) Thickness (t)

Temper | 1.6 mm | 3.2mm | 4.8mm | 6.0 mm | 10 mm |

0 | 0t | ½t | 1t | 1t | 1t |

H32 | ½t | 1t | 1t | 1½t | 1½t |

H34 | 1t | 1½t | 1½t | 2½t | 2½t |

H36 | 1½t | 2½t | 3t | 3½t | 4t |

H38 | 2½t | 3t | 4t | 5t | 5½t |

Aluminum can bodies/lids

Automotive fuel tanks, radiators

Ship decks/pipes

Building curtain walls/roofs

Chemical/food packaging containers

Air conditioning heat exchanger fins

Truck cargo linings, rail transit ventilation ducts

Solar water heater inner tanks

Interior ceilings/elevator interiors

Medical device housings

We adopts standard export shipping packaging and bundles steel strips according to the size of the aluminum sheet. According to our delivery experience, a 20-foot container can hold 22 tons of aluminum, and a 40-foot container can hold 25 tons of aluminum. Also, we can customize the packaging according to the needs of customers.

1. Cut to size: We can provide any size you need.

2. Dedicated person: A reliable sales person is always at hand.

3. On-time delivery: We have special team to ensure on-time delivery.

4. Reliable after-sale service: We have staff to deal with your appeal any time.

3003 aluminum sheet has a lower content of manganese, the core alloying element.

3004 aluminum, due to its magnesium content, belongs to the Al-Mn-Mg alloy system, with a richer content of strengthening elements.

3003 alloy has relatively low strength but excellent plasticity.

The solid solution strengthening of magnesium makes 3004 alloy significantly stronger than 3003 aluminum, with slightly lower plasticity.

3003 alloy: It has excellent cold working and welding (argon arc welding, resistance welding) performance,which can be easily rolled into thin plates and foils. Its bending is crack-free, and processing costs are low.

3004 alloy : It has good cold working performance, but due to its higher strength, the deformation rate needs to be controlled during deep drawing It has excellent welding performance and its processing difficulty is slightly higher than 3003.

Both have excellent resistance to atmospheric and freshwater corrosion and no tendency for stress corrosion. Due to the magnesium content, 3004 aluminum has slightly better resistance to marine climates and weak acid and alkali corrosion than 3003 alloy.

3003 aluminum: It focuses on low-strength, high-formability requirements, such as kitchenware, radiators, decorative panels, can lids, cable sheaths, etc.

3004 alloy: It is suitable for medium-strength applications, such as can bodies, food packaging containers, automotive fuel tanks, marine parts, air conditioner outdoor unit frames, etc.