With the aluminum’s lightweight and corrosion resistance, and high strength of steel, aluminum clad steel sheet is widely used in shipbuilding, offshore oil engineering, electrolytic aluminum, learn more.

Haomei aluminum-steel acp sheet is a bimetallic composite material formed by combining aluminum and steel plates through an explosive bonding process. They combine the corrosion resistance, lightweight, thermal and electrical conductivity of aluminum with the high strength, high rigidity, and good welding and forming properties of steel.

This overcomes the performance shortcomings of single metal materials and has significant comprehensive advantages in lightweight, corrosion protection, and structural load-bearing applications. Moreover, due to its high cost-effectiveness and adaptability to the needs of multiple industries, it has become one of the preferred materials to replace pure aluminum or pure steel structural components in the international market.

Product name | Aluminum clad steel sheet |

Cladding metal(aluminum) | 1050, 1060, 1100, 5083 1a97, 1a93,1a90, 1a85, |

Base metal(steel) | Q235, Q245R, Q345R, DH36, CCSB, 15CrMoR,16Mn, 20MnMo, 15CrMo, 109MnNiDR, 16MnD, 09MnNiD,etc. |

Size(mm) | 0.1-20/0.2-120x2000×6000 1-14/6-80x ﹤1000x ﹤4000 |

Implementation Standards | Q/XB1906-94、CB1343-1998 GB/T8546-2007 |

Application | Electrolytic aluminum, transition joints, ships, aerospace, instruments, cryogenic engineering, etc. |

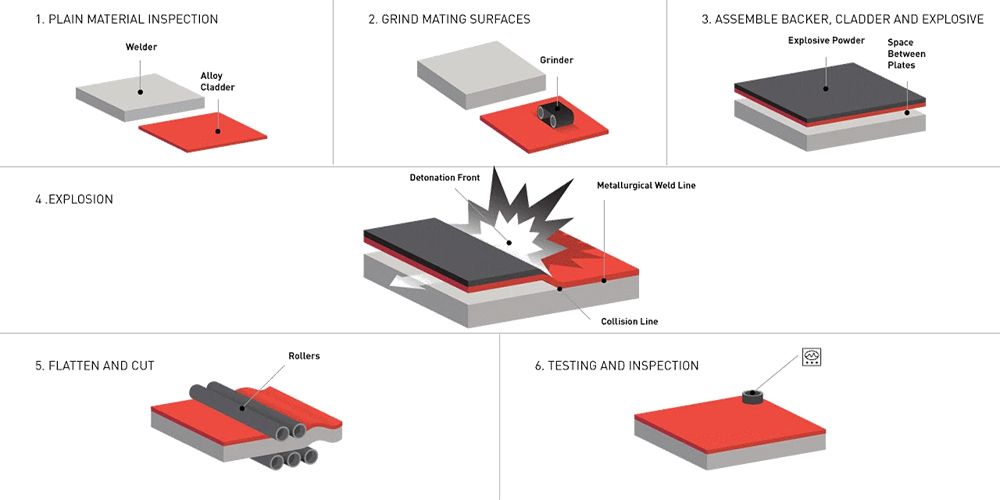

Explosive bonding, as a high-end manufacturing technology for aluminum-steel composite panels, boasts the core advantage of achieving metallurgical bonding between aluminum and steel interfaces through the instantaneous high temperature and pressure of an explosive explosion.

No intermediate layer is required, and the interfacial bonding strength can reach 80%–95% of the substrate strength. Furthermore, the transition zone is extremely thin (<50μm), maximizing the preservation of aluminum's corrosion resistance, thermal and electrical conductivity, and steel's high strength and rigidity.

This process has a wide range of applications, unaffected by differences in melting points or thermal expansion coefficients between the two metals. It can composite any grade of aluminum with steel and flexibly produce large-size (4m wide, 12m long), thick (3mm–100mm and above) composite panels with customized structures such as single-sided, double-sided, and multi-layer panels.

Simultaneously, the production process is completed instantaneously, without issues such as overheating or grain growth that degrade the substrate's performance. It also eliminates the need for large hot and cold rolling equipment, offering high tolerance for site and process errors, making it suitable for small-batch customized production. The finished products exhibit stable performance, good consistency, and a bonding strength deviation of ≤5%.

We provide aluminum clad steel sheet and aluminum steel transition joints. The main difference is the product size(as shown in the picture).

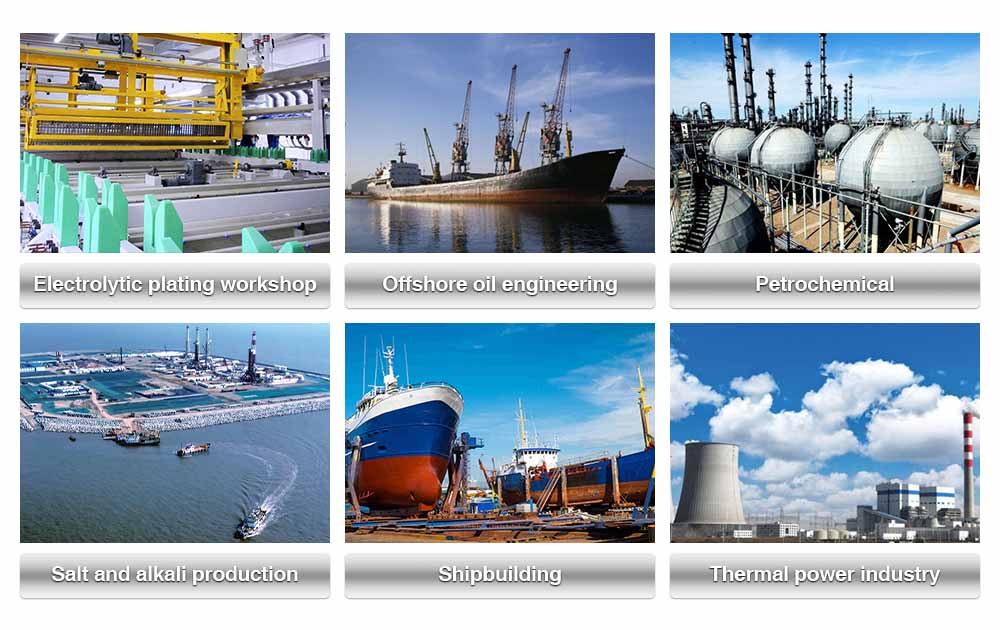

Aluminium ACP sheets, with their complementary advantages of the corrosion-resistant and lightweight aluminum layer and the high-strength and deformation-resistant steel layer, are widely used in transportation, construction decoration, petrochemicals, home appliances, electronics, and machinery manufacturing.

They can be used as structural components such as truck body panels, container side panels, and high-rise building curtain wall panels, as well as for manufacturing components such as oil storage tanks, pipelines, and appliance housings.

While meeting core requirements such as lightweight, corrosion resistance, and load-bearing capacity, they effectively reduce equipment weight and long-term maintenance costs, making them a cost-effective alternative to single-metal materials in the international market.

In the shipbuilding industry, aluminum-steel composite plates are ideal materials for both near-shore and ocean-going vessels. They are mainly used in components such as deck plates, cabin partition walls, side panels, seawater piping systems, and deck machinery protective covers.

The aluminum layer effectively resists corrosion from seawater and salt spray, significantly reducing the frequency and cost of corrosion protection maintenance after the vessel goes to sea, while the steel layer provides sufficient structural strength and impact resistance to cope with wind and wave loads and mechanical vibrations during navigation.

At the same time, compared with pure steel structural components, this composite plate can reduce the local weight of the hull, helping the vessel to increase its speed and reduce fuel consumption. It is especially suitable for the lightweight transformation needs of small and medium-sized fishing boats, yachts, and near-shore vessels. Some high-end ocean-going vessels also use it in superstructure components to further optimize the hull's center of gravity distribution and navigation stability.

Haomei Aluminum has always prioritized technology and quality, and has successively passed ISO9001-2008 quality management system certification, ISO14001-2004 environmental management system certification, and GB/T28001-2001 occupational health and safety management system certification. It has also obtained self-operated export qualification and has won high praise from users.