What Are Main Alloys of 1000 Series Aluminum

Oct 31 25

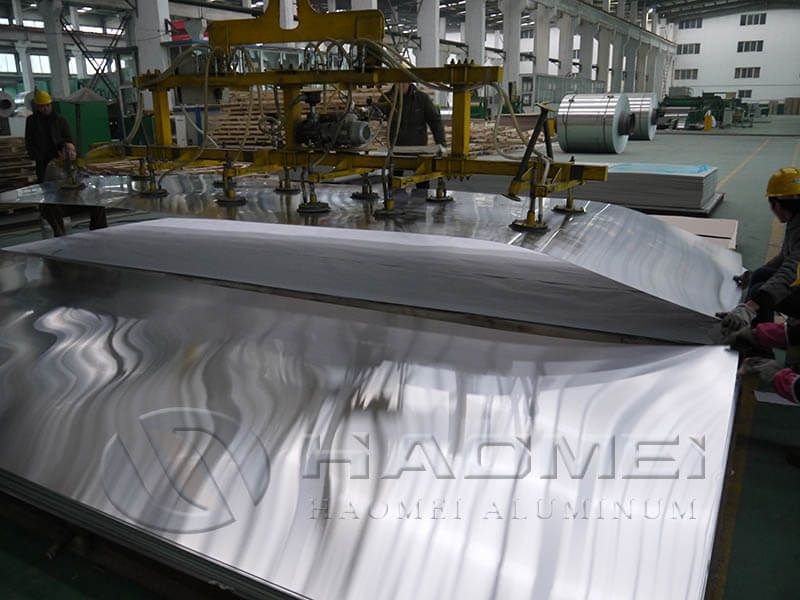

1000 series aluminum is a family of industrially pure aluminum grades containing at least 99.0% aluminum. These alloys cannot be strengthened through heat treatment and can only be strengthened through cold working. However, their excellent electrical conductivity (up to 61% of the international annealed copper standard), thermal conductivity, corrosion resistance, and plastic working properties have made them an irreplaceable material in a variety of fields.

Main alloy grades

1050 alloy

Key features: It has 99.50% aluminum content, a density of only 2.71g/cm³, and an elongation exceeding 30%. It offers excellent corrosion resistance and formability, exhibits no low-temperature brittleness, and actually exhibits increased strength and ductility at low temperatures.

Uses: As one of the most cost-effective industrial pure aluminum, 1050 aluminium sheet is widely used in food packaging foil, cookware, inland waterway vessel equipment, and refrigeration equipment components. In the food industry, its non-magnetic and non-sparking properties make it an ideal material for sauce jars and beverage bottle caps. In the construction sector, it is often processed into decorative aluminum plates and nameplates.

1060 alloy

Core features: Its aluminum content is increased to 99.60%, resulting in improved electrical and thermal conductivity, reaching approximately 50% of the international standard. The surface can be easily anodized and colored, creating a variety of decorative effects.

Uses: This grade is widely used in conductive poles and busbars in the power industry. Architectural curtain walls and interior decorative panels purchase large quantities of 1060 aluminum sheet for its gloss and weather resistance. It is also a core material for small heat exchanger and instrument housings, and its demand is growing significantly in small heat dissipation components for new energy vehicles.

1100 aluminum

Main features: This improved pure aluminum grade contains a small amount of copper, owning a tensile strength of 110-150 MPa (higher than 1060's 70-110 MPa), improved machinability, and excellent weldability and corrosion resistance.

Uses: It targets lightweight and lightly stressed applications, such as cookware handles, washing machine drums, and highway sign substrates. In the chemical industry, its corrosion resistance makes it a common material for small reaction vessels. Shielding covers for electronic devices also favor this grade, as they require a balance between formability and structural strength.

Market demand

The demand landscape for 1000 series aluminum alloys shows a pattern of "stable traditional sectors and expanding emerging sectors":

Stable packaging industry: 1145 and 1235 aluminum foil, driven by their food safety and ease of processing, are consumed in snack and pharmaceutical packaging at an annual rate exceeding one million tons.

Expanding power sector: 1350 aluminum alloys are seeing increased demand alongside the construction of ultra-high voltage power grids, with the market size projected to exceed 2 billion yuan in 2026.

Growing architectural decoration field: 1060 anodized sheet metal now accounts for 35% of green building applications, replacing some stainless steel decorative materials.

Emerging applications: 1199 electrolytic capacitor foil is experiencing a surge in demand for new energy storage devices, and 1070A optical reflective film has become a key material for photovoltaic and solar thermal systems.

https://www.alsheetplate.com/a/what-are-main-alloys-of-1000-series-aluminum.html