5754 Aluminum Alloy Sheet

5754 Aluminum

5754 is an Al-Mg-based rust-resistant aluminum with a magnesium content of 2.6-3.6%, a tensile strength of 190-240 MPa (in the O phase), and excellent corrosion resistance, making it suitable for harsh environments such as ships and pressure vessels. It is non-heat treatable. Compared to 5052 aluminum sheet, it has higher strength, but 5052 has better formability. 5251 aluminum has higher processing efficiency.

5754 alloy chemical composition(%)

Mn | Fe | Mg | Si | Cr | Cu | Mn+Cr | Ti | Zn | Other (each) | Other (total | Al |

0.0-0.5 | 0.0-0.4 | 2.6-3.6 | 0.0-0.4 | 0.0-0.3 | 0.0-0.1 | 0.1-0.6 | 0.0-0.15 | 0.0-0.20 | 0.0-0.05 | 0.0-0.15 | Balance |

Specification

Alloy | 5754 aluminum sheet |

Thickness(mm) | 0.2-200 |

Length(mm) | 500-13000 |

Width(mm) | 30-2500 |

Main tempers

Tempers | Tensile strength | Yield strength | Elongation |

O | 180-240 MPa | 80-150 MPa | ≥12% |

H111 | 160-200 MPa | ≥60 MPa | ≥12% |

H22 | 220-270 MPa | ≥130 | 7% |

H12 | 200-240 MPa | 90-130 MPa | 9-11% |

H14 | 220-260 MPa | 110-160 MPa | 8% |

H24 | 240-280 MPa | 160 MPa | 6% |

H26 | 265-305 MPa | 190 MPa | 4% |

Other names of 5754 aluminum

AA5754

EN AW-5754

A5754

A95754

Al Mg3

Al 3.1Mg Mn Cr

AW 5754

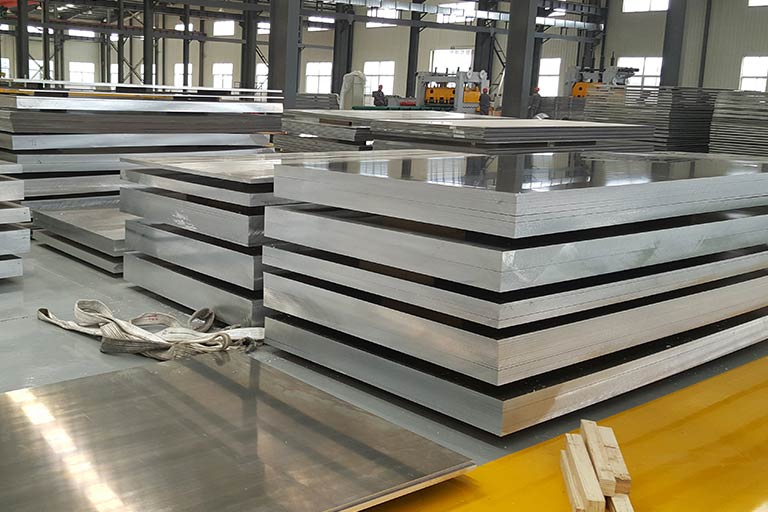

Supplied forms

Application

Shipbuilding

Vehicle bodies

Rivets

Fishing industry equipment

Food processing

Tank Truck

Curtain wall panels, ceilings, aluminum alloy door and window frames

Small mechanical equipment casings, instrument and meter protective housings

Radiators

Packaging &shipping

We adopts standard export shipping packaging and bundles steel strips according to the size of the aluminum sheet. According to our delivery experience, a 20-foot container can hold 22 tons of aluminum, and a 40-foot container can hold 25 tons of aluminum. Also, we can customize the packaging according to the needs of customers.